Review Article - (2024) Volume 15, Issue 4

Abstract

The evaluation of diclofenac potassium tablets involved rigorous testing to ensure quality and efficacy. Tests included hardness assessment to gauge tablet strength, friability testing to determine resistance to action analysis was conducted to ensure uniformity among tablets. This comprehensive Ethylene-Vinyl Acetate (EVA) abrasion and disintegration tests to assess dissolution properties. Additionally, weight evaluation provides valuable insights into the tablets physical characteristics, aiding in the assurance of product quality and consistency. This study focuses on the comprehensive evaluation of diclofenac potassium tablets, an important step in ensuring their quality and performance. Hardness testing was employed to measure the tablets resistance to breakage, indicating their strength and durability. Friability assessment gauged the tablets susceptibility to abrasion, providing insights into their structural integrity during handling and transport. Disintegration tests were conducted to examine the tablets dissolution properties, important for predicting their efficacy upon ingestion. Weight variation analysis ensured uniformity in tablet mass, a critical factor in dosage accuracy and overall product consistency. The findings from these tests collectively contribute to a thorough understanding of the physical attributes of diclofenac potassium tablets. This information is essential for quality control, helping to guarantee that each tablet meets the required standards for hardness, friability, disintegration, and weight variation. As a result, this evaluation provides valuable data for pharmaceutical manufacturers, regulatory authorities, and healthcare professionals, reinforcing the reliability and effectiveness of diclofenac potassium tablets in therapeutic applications.

Keywords

Diclofenac potassium, Dissolution, Friability, Antipyretic, Non-steroidal anti-inflammatory drug

Introduction

Evaluation of the general marketed tablets

According to the United States Pharmacopeia (USP), tablets are solid dosage forms, containing medicinal substances with or without suitable diluents. They may be classed, according to the method of manufacture, as compressed tablets or moulded tablets. Tablets have been in widespread use, since the later part of the 19th century, and their popularity continues. The term “compressed tablet” is believed to have been first used by John Wyeth and Brother, Inc. of Philadelphia (Adejare A, 2020; Lachman L, et al., 1976; WebMD, 2005).

Although tablets are frequently discoid in shape, they also may be round, oval, oblong, cylindrical or triangular. Other geometric shapes, such as diamonds, pentagons, and hexagons have also been used. They may differ in size and weight, depending on the amount of drug substance present and the intended method of administration. Most commercial tablets can be divided into two general classes-whether they are made by compression or moulding. Compressed tablets are prepared by large-scale production methods whereas moulded tablets involve small scale operations. The various tablet types and abbreviations used in referring to them are listed here.

Liquid oral dosage forms have other disadvantages and limitations when compared with tablets. They are much more expensive to ship (one liquid dosage weighs 5 g or >0.25 g to 0.40 g for the average tablet), and breakage or leakage during shipment is a more serious problem with liquids than with tablets.

Advantages

One of the major advantages of tablets over capsules, which has recently proved significant, is that the tablet is an essentially tamper proof dosage form. The major advantage of capsules is theirability to hide their contents from sight and to mask or hide the taste or odour of their contents and makes them the most vulnerable to tampering of all dosage forms.

• They are a unit dosage form, and offer the greatest capabilities of all oral dosage form for the greatest dose precision and least content variability.

• Their cost is lowest of all oral dosage forms.

• They are the lightest and most compact of all oral dosage forms.

• They are better suited to large-scale production than other unitoral forms.

• They lend themselves to certain special release profile products, such as enteric or delayed release products.

• Their cost is lowest of all oral dosage forms.

Disadvantages

The disadvantages of tablets include the following-

• Some drugs resist compression into dense compacts, owing to their amorphous nature or flocculent, low density character.

• Drugs with poor wetting, slow dissolution properties, intermediate to large dosages, optimum absorption high in the gastrointestinal tract, or any combination of these features may be difficult or impossible to formulate and manufacture as a tablet that will still provide adequate or full drug bioavailability (Kara DD, et al., 2021).

• Bitter tasting drugs, drugs with an objectionable odour or drugs that are sensitive to oxygen or atmospheric moisture may require encapsulation or entrapment prior to compression (if feasible or practical) or the tablets may require coating. In such cases, the capsule may offer the best and lowest cost approach.

Types of tablets

1. Compressed Tablet (CT): Compressed tablets are formed by compression and, in their simplest form, contain no special coating.

2. Sugar Coated Tablet (SCT): Sugar-coated tablets are compressed tablets surrounded by a sugar coating.

3. Film Coated Tablet (FCT): Film coated tablets are compressed tablets covered with a thin layer or film of a water-soluble material.

4. Enteric Coated Tablet (ECT): Enteric coated tablets are compressed tablets coated with substances that resist solution in gastric fluid but disintegrate in the intestine.

5. Multi Compressed Tablet (MCT): Multi-compressed tablets are compressed tablets made by more than one compression cycle.

6. Layer tablet: Layered tablets are prepared by compressing additional tablet granulation on a previously compressed granulation.

7. Press coated tablet: Press coated tablets, also referred to as dry-coated tablets, are prepared by feeding previously compressed tablets into a special tableting machine and compressing another granulation layer around the preformed tablets.

8. Controlled Release Tablet (CRT): Compressed tablets can be formulated to release the drug slowly over a prolonged period of time.

9. Tablets for Solution (CTS): Compressed tablets used for preparing solutions or imparting given characteristics to solutions must be labelled to indicate they are not to be swallowed. Examples of these tablets are Halazone tablets for solution and potassium permanganate tablets for solution.

10. Effervescent tablets: In addition to the drug substance, effervescent tablets contain sodium bicarbonate and an organic acid, such as tartaric or citric.

11. Compressed suppositories or inert: Occasionally, vaginal suppositories, such as metronidazole tablets, are prepared by compression.

12. Buccal and sublingual tablets: Buccal and sublingual tablets are small, flat, oval tablets. Tablets intended for buccal administration by inserting into the buccal pouch (the space between the lip and gum in the mouth) may dissolve or erode slowly; therefore, they are formulated and compressed with sufficient pressure to give a hard tablet. Progesterone tablets may be administered in this way. Some newer approaches have employed materials that act as bioadhesives to increase absorption of the drug.

13. Hypodermic Tablets (BT): Hypodermic tablets are soft, readily soluble tablets and were originally used for the preparation of solutions to be inject since stable parenteral so justification for moulding substances, there is no justification for the use of dermic tablets for injection.

14. Compressed Tablets (CT): For medicinal substances, with or without diluents, to be made into solid dosage forms with pressure, using available equipment, it is necessary that the material, either in crystalline or powdered form, possess a number of physical characteristics. These characteristics include the ability to flow freely, cohesive-ness, and lubrication.

Literature Review

According to the study carried by (Ali H, et al., 2016; Azam M, et al., 2022), updated the formulation and evaluation of diclofenac potassium whose aim was to determine the pharmacokinetic and bioequivalence of diclofenac potassium 50 mg test (F4) tablet formulation with reference product (Caflam). Present study was single dose, randomized, two phase cross over design, conducted in 12 healthy Pakistani volunteers and planned in accordance with FDA guidelines. In this study a simple, selective, sensitive and reproducible HPLC procedure was developed and validated for the estimation of diclofenac potassium in plasma (Rubim AM, et al., 2013; Iacovides S, et al., 2009).

As per the study carried by (Altman R, et al., 2015), updated the formulation and evaluation of diclofenac potassium to determine the objective of the study was to develop HPMC matrix tablets for oral controlled/ sustained release of water soluble diclofenac potassium. Sustained release matrix tablets containing 100 mg of diclofenac potassium were developed using different drug polymer ratio of HPMC. Tablets were prepared by direct compression. Compressed tablets were evaluated for uniformity of weight, content of active ingredient, friability, hardness, thickness and in vitro dissolution study (Patil BS, et al., 2010).

The study carried by (Moore N, et al., 2007), updated the review on evaluation of diclofenac potassium tablet to determine the objective of the study was to develop HPMC matrix tablets for oral controlled/sustained release of water soluble diclofenac potassium. Sustained release matrix tablets containing 100 mg of diclofenac potassium were developed using different drug polymer ratio of HPMC. Tablets were prepared by direct compression. Compressed tablets were evaluated for uniformity of weight, content of active ingredient, friability, hardness, thickness and in vitro dissolution study. All tablets but one exhibited gradual and near completion sustained release for diclofenac potassium and 98.72% released at 12 hours. The results of dissolution studies indicating that formulation D5 (drug to polymer 1:1.40) the most successful of the study, exhibited drug release pattern very close to theoretical release profile. A decrease in release kinetic of the drug was observed on increasing polymer ratio.

The study carried by (Dahivelkar PP, et al., 2012), updated the review on formulation and evaluation of diclofenac potassium to determine a rapid, simple and low cost method was developed to determine Diclofenac Potassium (DP) in oral suspension, using a reverse-phase column (C8, 150 mm × 4.6 mm, 5 µm), mobile phase containing methanol/buffer phosphate (70:30 v/v, pH 2.5), at a flow rate of 1.0 ml/min, isocratic method, and ultraviolet detection at 275 nm. A linear response (r=1.0000) was observed in the range of 10.0-50.0 µg/ml. Validation parameters such as linearity, specificity, precision, accuracy and robustness were evaluated (Comoglu T, et al., 2011).

Discussion

Drug profile

Diclofenac potassium tablets USP are a benzeneacetic acid derivative. Diclofenac potassium tablets USP, 50 mg are available as orange, film-coated tablets for oral administration. The chemical name is 2-[(2,6- dichlorophenyl)amino] benzeneacetic acid, monopotassium salt.

Diclofenac potassium is a faintly yellowish white to light beige, virtually odorless, slightly hygroscopic crystalline powder. It is freely soluble in methanol, soluble in ethanol and water, and practically insoluble in chloroform and in dilute acid; n-octanol/water partition coefficient is 13.4 at pH 7.4 and 1545 at pH 5.2. It has a single dissociation constant (pKa) of 4.0 ± 0.2 at 25ºC in water.

Each tablet, for oral administration, contains 50 mg of diclofenac potassium. In addition, each tablet contains the following inactive ingredients: Colloidal silicon dioxide, corn starch, FD and C Blue No. 2, FD and C Red No. 40, FD and C Yellow No. 6, hypromellose, lactose monohydrate, magnesium stearate, microcrystalline cellulose, polyethylene glycol 4000, povidone, sodium starch glycolate, titanium dioxide, and tricalcium phosphate.

Pharmacodynamics: Diclofenac potassium tablets are a Non-Steroidal Anti-Inflammatory Drug (NSAID) that exhibits anti-inflammatory, analgesic, and antipyretic activities in animal models. The mechanism of action of diclofenac potassium tablets, like that of other NSAIDs, is not completely understood but may be related to prostaglandin synthetize inhibition. Uses: This powder form of diclofenac is used to treat migraine headaches. Diclofenac is not used to prevent migraines from happening or lessen how often you get them. Diclofenac is known as a Non-Steroidal Anti-Inflammatory Drug (NSAID). It works by blocking your body’s production of certain natural substances that cause inflammation. This effect helps to decrease swelling, pain and fever.Evaluation parameters of diclofenac potassium

Evaluation parameters such as, appearance, testing of hardness, friability, tablet thickness, disintegration time and uniformity of weight were evaluated, where primarily the appearance of diclofenac tablet was assessed as shown in (Table 1).

| Appearance | Multi-coloured circular biconvex tablet plain on both side |

| Right | complies |

| Left | complies |

Table 1: Appearance of diclofenac potassium

Hardness test: Hardness test is the most important feature for assessing tablet in the study it was found that tablet passed the test of tablet crushing strength or hardness both these brands have acceptable crushing strength of between 5 kg/cm2 to10 kg/cm2 this test done from Pfizer test machine (Figures 1 and 2). Approximately one decade later, the Pfizer tester was developed and made available to the industry. This tester operates on the same mechanical principle as a pair of pliers. As the plier’s handles are squeezed, the tablet is compressed between a holding anvil and a piston connected to a direct force reading gauge. The dial indicator remains at the reading where the tablet breaks and is returned to zero by depressing a reset button. Pfizer tester became extensively used in comparison to the earlier testers, based on its simplicity, low cost and the rapidity with which it could be used. Hardness of diclofenac was found to be 6.4, as per our study (Table 2). The tablets hardness is within acceptable limits, ensuring stability and resistance to breakage during handling and transportation.

| No. of tablets | 1 | 2 | 3 | 4 | 5 | Hardness |

| Hardness (kg/cm2) | 6 | 7 | 6 | 7 | 6 | 6.4 |

Table 2: Results of hardness test of diclofenac potassium

Figure 1: Chemical structure of Valsartan

Figure 2: Monsanto hardness tester

Friability: A tablet property related to hardness is friability, and the measurement is made by use of the Roche friabilator. Rather than a measure of the force required to crush a tablet, the instrument is designed to evaluate the ability of the tablet to withstand abrasion in packaging, handling, and shipping. A number of tablets are weighed and placed in the tumbling apparatus, where they are exposed to rolling and repeated shocks, resulting from free-falls within the apparatus. After a given number of rotations, the tablets are weighed, and the loss in weight indicates the ability of the tablets to withstand this type of wear (Figure 3). The friability test is now included in the USP. A similar approach is taken by many manufacturers, when they evaluate a new product in the new market package by sending the package to distant points and back using various methods of transportation. This is called a shipping test. The condition of the product on its return indicates its ability to withstand transportation handling.

Figure 3: Monsanto hardness tester

% friability=W1-W2/W1 × 100

Where, W1=Weight of table before test and W2=Weight of table after test

Weight of the 20 tablets was found to be 11.593 gm

Weight of 20 tablets after rotation was expressed as 11.587 gm where the % friability was 0.12%. Low friability indicates good durability, minimizing the risk of tablet deterioration and ensuring intactness under normal conditions.

Tablet thickness: The thickness of the tablet from production run to production run was controlled carefully. Thickness can vary with no change in weight, due to difference in the density of the granulation and the pressure applied to the tablets, as well as the speed of tablet compression. Apart from the tablet thickness it is equally important to ensure that every production lot should be usable with selected packaging components while reproducing tablets identical in appearance. If the tablets are thicker than specified, a given number no may longer be contained in the volume of a given size bottle. Tablet thickness also becomes an important characteristic in counting tablets using filling equipment. Some filling equipment uses the uniform thickness of the tablets as a counting mechanism. A column containing a known number of tablets is measured for height; filling is accomplished by continually dropping columns of tablets of the same height into bottles. If thickness varies throughout the lot, the result will be variation in count. Other pieces of filling equipment can malfunction, due to variation in tablet thickness, since tablets above specified thickness may cause wedging of tablets in previously adjusted depths of the counting slots. Tablet thickness is determined with a calliper or thickness gauge that measures the thickness (mm); ± 5% may be allowed, depending on the Standard Operating Procedures (SOP) (Table 3). The tablet thickness falls within specified standards, contributing to ease of swallowing and consistent dosing accuracy.

| No. of tablets | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Thickness (mm) | 4.9 | 5.1 | 4.9 | 5.2 | 5.3 | 5 | 5.1 | 5.2 | 4.9 | 5 |

| Diameters (mm) | 8 | 8.5 | 8.3 | 8.2 | 8.8 | 8.5 | 8.6 | 8.7 | 8.8 | 9 |

Table 3: Analysis of diclofenac potassium tablet thickness

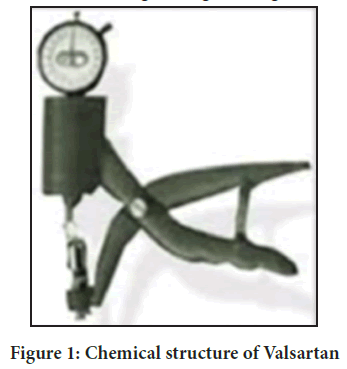

Disintegration time: The USP gadget to test crumbling utilizes 6 glass tubes that are 3 long; open at the top and 10 cross section screens at the base end (Figure 4). To test for deterioration time, one tablet is put in each cylinder and the crate rack is situated in a 1 l measuring utensil of water, re-enacted gastric liquid or reproduced gastrointestinal liquid at 37 ± 20°C with the end goal that the tablet stay 2.4 cm beneath the outer layer of fluid on their vertical development and not nearer than 2.4 cm from the lower part of the measuring glass in their descending development. Move the bin containing the tablets all over through a distance of 5 cm-6 cm at a recurrence of 28-32 cycles each moment. During of the tablets can before stalled by putting punctured plastic circles one very tablet. The tablet exhibits a desirable disintegration time, implying effective dissolution for optimal absorption and therapeutic efficacy.

Figure 4: Disintegration test apparatus

Uniformity of weight: 20 tablets are weighed. The average weight was determined. Then, tablets were weighed individually and for each tablet, the % of deviation of its weight from the average weight was determined (Tables 4 and 5). The deviation of individual weight from the average weight should not exceed the limits given.

| No. of tablets | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Weight (mg) | 551 | 580 | 585 | 590 | 591 | 598 | 600 | 587 | 578 | 569 |

| Pass/fail | Pass | pass | pass | pass | pass | Pass | pass | pass | Pass | pass |

Table 4: Analysis of tablet weight (diclofenac potassium)

| Evaluation parameters | Observation |

|---|---|

| Appearance | Multi coloured circular biconvex tablet plain on both side |

| Hardness | 6.4 kg/cm |

| Friability | 0.12% |

| Disintegration test | 3.2 min (<5min ) |

| Uniformity of weight | All passes ± 2% |

| Thickness | 5.06 mm |

Table 5: Result of evaluation

Conclusion

Overall, the evaluation parameters for tablets, including hardness, friability, disintegration time, uniformity of weight, and thickness, are crucial in determining the quality and effectiveness of these medications. A tablet that is too soft or crumbles easily may not be effective, while one that is too hard may be difficult to swallow or digest. Additionally, disintegration time and uniformity of weight are essential indicators of dosage consistency, which is key for patient safety and medication effectiveness. In order to ensure the highest quality of tablets, it is important to carefully measure and evaluate these parameters, and make any necessary adjustments during the manufacturing process.

References

- Adejare A. Remington: The science and practice of pharmacy. Academic press. 2020.

- Lachman L, Lieberman HA, Kanig JL. The theory and practice of industrial pharmacy. 1976.

- WebMD. 2005.

- Kara DD, Govindarajulu HK, Shivaprasad H, Krishna V, Tippavajhala MJ, Kulyadi GP. Detailed research on a comparative evaluation of diclofenac sodium tablets manufactured by using DC grade excipients and wet granulation methods. Indian J Pharm Educ Res. 2021; 55(3): 722-732.

- Ali H, Shoaib MH, Zafar F, Hanif M, Bushra R, Naz A, et al. Pharmacokinetic and bioequivalence studies of immediate release diclofenac potassium tablets (50 mg) in healthy volunteers. Pak J Pharm Sci. 2016; 29(5): 1671-1679.

[Google scholar] [Pubmed]

- Azam M, Sodiyal N, Sivanadpatil. A review on evaluation of tablet. Int J Res Eng Sci. 2022; 10(4): 79-82.

- Rubim AM, Rubenick JB, Laporta LV, Rolim CM. A simple method for the quantification of diclofenac potassium in oral suspension by high-performance liquid chromatography with UV-detection. Braz J Pharm Sci. 2013; 49: 589-597.

- Iacovides S, Avidon I, Bentley A, Baker FC. Diclofenac potassium restores objective and subjective measures of sleep quality in women with primary dysmenorrhea. Sleep. 2009; 32(8): 1019-1026.

[Crossref] [Google scholar] [Pubmed]

- Altman R, Bosch B, Brune K, Patrignani P, Young C. Advances in NSAID development: Evolution of diclofenac products using pharmaceutical technology. Drugs. 2015; 75: 859-877.

[Crossref] [Google scholar] [Pubmed]

- Patil BS, Kulkarni U, Bhavik P. Formulation and evaluation of diclofenac potassium matrix tablets. Int J Pharm Sci Res. 2010; 1(8): 88-92.

- Moore N. Diclofenac potassium 12.5 mg tablets for mild to moderate pain and fever: A review of its pharmacology, clinical efficacy and safety. Clin Drug Investig. 2007; 27(3): 163-195.

[Crossref] [Google scholar] [Pubmed]

- Dahivelkar PP, Bhoir SI, Bari SB, Surana SJ, Bhagwat AM. Simultaneous determination of diclofenac potassium and drotaverine hydrochloride in human plasma using reversed-phase high-performance liquid chromatography. J Chromatogr Sci. 2012; 50(8): 694-701.

[Crossref] [Google scholar] [Pubmed]

- Comoglu T, Dogan A, Comoglu S, Basci N. Formulation and evaluation of diclofenac potassium fast-disintegrating tablets and their clinical application in migraine patients. Drug Dev Ind Pharm. 2011; 37(3): 260-267.

[Crossref] [Google scholar] [Pubmed]

Author Info

Bharat Jadhav*, Rutja Daas and Sahil T SheikhReceived: 25-Mar-2024 Accepted: 10-Apr-2024 Published: 17-Apr-2024, DOI: 10.31858/0975-8453.15.4.156-160

Copyright: This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

ARTICLE TOOLS

- Dental Development between Assisted Reproductive Therapy (Art) and Natural Conceived Children: A Comparative Pilot Study Norzaiti Mohd Kenali, Naimah Hasanah Mohd Fathil, Norbasyirah Bohari, Ahmad Faisal Ismail, Roszaman Ramli SRP. 2020; 11(1): 01-06 » doi: 10.5530/srp.2020.1.01

- Psychometric properties of the World Health Organization Quality of life instrument, short form: Validity in the Vietnamese healthcare context Trung Quang Vo*, Bao Tran Thuy Tran, Ngan Thuy Nguyen, Tram ThiHuyen Nguyen, Thuy Phan Chung Tran SRP. 2020; 11(1): 14-22 » doi: 10.5530/srp.2019.1.3

- A Review of Pharmacoeconomics: the key to “Healthcare for All” Hasamnis AA, Patil SS, Shaik Imam, Narendiran K SRP. 2019; 10(1): s40-s42 » doi: 10.5530/srp.2019.1s.21

- Deuterium Depleted Water as an Adjuvant in Treatment of Cancer Anton Syroeshkin, Olga Levitskaya, Elena Uspenskaya, Tatiana Pleteneva, Daria Romaykina, Daria Ermakova SRP. 2019; 10(1): 112-117 » doi: 10.5530/srp.2019.1.19

- Dental Development between Assisted Reproductive Therapy (Art) and Natural Conceived Children: A Comparative Pilot Study Norzaiti Mohd Kenali, Naimah Hasanah Mohd Fathil, Norbasyirah Bohari, Ahmad Faisal Ismail, Roszaman Ramli SRP. 2020; 11(1): 01-06 » doi: 10.5530/srp.2020.1.01

- Manilkara zapota (L.) Royen Fruit Peel: A Phytochemical and Pharmacological Review Karle Pravin P, Dhawale Shashikant C SRP. 2019; 10(1): 11-14 » doi: 0.5530/srp.2019.1.2

- Pharmacognostic and Phytopharmacological Overview on Bombax ceiba Pankaj Haribhau Chaudhary, Mukund Ganeshrao Tawar SRP. 2019; 10(1): 20-25 » doi: 10.5530/srp.2019.1.4

- A Review of Pharmacoeconomics: the key to “Healthcare for All” Hasamnis AA, Patil SS, Shaik Imam, Narendiran K SRP. 2019; 10(1): s40-s42 » doi: 10.5530/srp.2019.1s.21

- A Prospective Review on Phyto-Pharmacological Aspects of Andrographis paniculata Govindraj Akilandeswari, Arumugam Vijaya Anand, Palanisamy Sampathkumar, Puthamohan Vinayaga Moorthi, Basavaraju Preethi SRP. 2019; 10(1): 15-19 » doi: 10.5530/srp.2019.1.3